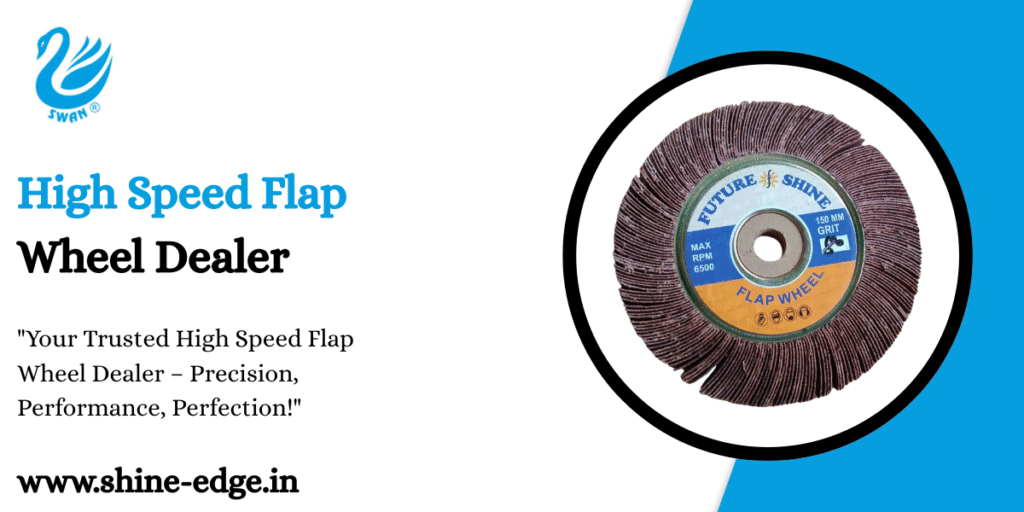

High Speed Flap Wheel Dealer

Introduction

Shine Edge is the manufacturer and supplier of coated & Bonded Abrasives products. We have state of art facilities to make Fibre discs, Flap discs, Flap wheels, lamellar wheels, and cutting wheels. Also, we are authorized distributors of Orient Abrasives, John Okay, Polymak, Karbit, and Rohit Cutting Tools.

In the fast-paced world of fabrication, finishing, and manufacturing, getting that perfect surface is frequently what separates excellent from great. The correct abrasive tool can have a big impact on your productivity, output quality, and eventually your bottom line, regardless of whether you’re working with metal, wood, or even plastics. Furthermore, High-Speed Flap Wheels are far superior to the competition in terms of speed, adaptability, and finish. We are the best High Speed Flap Wheel Manufacturer.

We at Shine Edge are aware of how important these tools are to a variety of sectors. As a top dealer of high-speed flap wheels, we’ve established a solid reputation for offering superior abrasive solutions. We’re here to explain why these wheels are so important and how Shine Edge can be your reliable partner in attaining abrasive greatness.

What Makes High-Speed Flap Wheels

Imagine an abrasive tool that minimizes heat accumulation and operator fatigue while achieving exceptional speed and precision in grinding, deburring, blending, and finishing. That is a high-speed flap wheel’s power. Flap wheels are made with several overlapping abrasive flaps centered around a central hub, in contrast to conventional grinding discs or sanding belts. There are several advantages to this unusual construction. We are the best High Speed Flap Wheel Supplier.

Why Choose Shine Edge

- Unwavering Quality Products: At Shine Edge, we recognize that the output quality is directly impacted by the tools’ performance. For this reason, we carefully choose and provide only the best high-speed flap wheels. Premium abrasive grains and sturdy backing materials are used in the manufacturing of our goods, guaranteeing exceptional cutting performance, a long lifespan, and reliable results on every project.

- Broad Selection to Meet All Needs: We have a large selection of high-speed flap wheels to meet a variety of commercial and residential needs. We have the appropriate grit, size, abrasive substance (aluminum oxide, zirconia, ceramic), and configuration (mounted, unmounted, various diameters and widths) to fit your particular application, whether you need wheels for aggressive stock removal, precise finishing, or polishing.

- Professional Advice and Assistance: The abrasives industry can be complicated. At Shine Edge, we have a team of skilled experts who are committed to seeing you succeed. We provide knowledgeable guidance in addition to orders. Are you unsure about which grit is ideal for your stainless steel project? Do you need advice on how to deburr complex metal parts? Our experts will help you choose the ideal high-speed flap wheel, guaranteeing both cost-effectiveness and peak performance.

- Competitive Pricing and Outstanding Value: In our opinion, superior quality shouldn’t be accompanied by a hefty price tag. Shine Edge is dedicated to providing affordable prices without sacrificing the quality of its products. Our durable flap wheels are incredibly affordable, lowering your total abrasive usage and improving your bottom line.

- Dependability and On-Time Delivery: We are aware of how expensive downtime can be. As a committed dealer, we place a high value on dependable support and prompt order delivery. You can be confident that Shine Edge will deliver your high-speed flap wheels on schedule, ensuring that your business operations remain effective and seamless.

- Customer-Centric Approach: We put your satisfaction first. By offering unmatched customer service, we hope to establish enduring relationships with our clients. The Shine Edge staff is committed to providing a smooth and satisfying experience from the first inquiry to the post-purchase assistance. We pay attention to your needs, act quickly, and put in great effort to go above and beyond your expectations.

- Innovation and Emerging Technologies: The abrasive sector is always changing. Shine Edge remains at the forefront of these developments by consistently adding the newest and most effective high-speed flap wheel technology to our product lineup. This guarantees that you will always have access to state-of-the-art solutions that can improve your output and final product quality.

Applications of High Speed Flap Wheels

- After welding, flap wheels are ideal for smoothing out high areas and integrating the weld bead into the parent material to create a “invisible weld” appearance.

- Deburring and Edge Breaking: Flap wheels effectively soften edges and remove sharp burrs from sheet metal and machined items, improving both safety and appearance.

- Aggressive Stock Removal: They can handle demanding grinding jobs like chamfering thick plates or eliminating extra material from castings if the right grit and density are used.

- Surface Preparation: Flap wheels efficiently remove rust, scale, old paint, and impurities before to painting, coating, or plating, guaranteeing the best possible adherence and finish lifetime.

- Finishing and merging: On a variety of metals, including stainless steel, they are perfect for achieving a consistent brushed appearance, merging varied grain patterns, and producing uniform, visually appealing finishes.

- Woodworking: For sanding and finishing wood, flap wheels work wonders, particularly on curved or contoured surfaces. They can smooth off rough spots, eliminate flaws, and get wood ready for painting or staining.

- Plastics and Composites: They are appropriate for finishing and deburring plastics and composite materials, reducing the chance of melting or distortion, due to their conformability and reduced heat generation.

- Automotive Industry: High-speed flap wheels are essential to the production and maintenance of automobiles, from bodywork and component finishing to rust treatment and surface preparation.

- Maintenance and Repair: In a variety of maintenance and repair tasks in both residential and commercial contexts, they are indispensable for cleaning, prepping, and refinishing surfaces.

Specifications Table of High-Speed Flap Wheels

| Parameter | Description |

|---|---|

| Brand | Shine Edge |

| Product Type | High Speed Flap Wheel |

| Diameter | 25mm – 300mm |

| Width | 10mm – 100mm |

| Shank Diameter | 6mm, 8mm (or as per request) |

| Grit Sizes Available | 40, 60, 80, 100, 120, 180, 240, 320 |

| Abrasive Material | Aluminum Oxide (AO), Zirconia Alumina (ZA), Ceramic |

| Bonding | Resin Bond |

| Backing | Cotton, Polyester, or Blend Cloth |

| Max Speed | Up to 25,000 RPM |

| Recommended Machine | Angle Grinder, Die Grinder, Bench Grinder |

| Custom Options | Available |

| Packing Type | Box / Carton / Bulk Export Packaging |

| Country of Origin | India |

Benefits of High-Speed Flap Wheels

- Very Effective and Quick Stock Removal: These wheels are incredibly effective at removing material because of their vigorous cutting action and continuous exposure of fresh abrasive grains. You will save a lot of time on your projects as a result.

- High-quality Finish: Flap wheels offer a smoother, more uniform finish than conventional grinding wheels, which have the ability to gouge surfaces. They can create a homogeneous surface by adapting to uneven shapes and contours because to their flexibility.

- Versatility for Multiple Applications: A single flap wheel may frequently manage several task stages, ranging from demanding deburring and weld removal to fine finishing and polishing. Wood, polymers, and a variety of metals, both ferrous and non-ferrous, can all be effectively treated with them.

- Decreased Heat Buildup: Flap wheels’ overlapping flap design promotes improved heat dissipation and air circulation. This lessens the amount of heat that accumulates on the workpiece, which lowers the possibility of damage, discoloration, or warping especially for delicate materials.

- Improved Operator Comfort and Safety: Flap wheels frequently generate less noise and vibration than rigid grinding wheels, which makes the user experience more comfortable and less taxing. Additionally, its flexibility improves safety by reducing the likelihood of gouging and kickback.

- Extended Service Life and Cost-Effectiveness: Although high-speed flap wheels may initially cost a little more than ordinary sandpaper, their long lifespan and reliable performance make them a much more cost-effective option over time. Reduced downtime and overall operating expenses result from fewer replacements.

- Access to Hard-to-Reach Areas: Where other abrasive tools might find it difficult to operate in confined areas, intricate designs, or the inside of pipes or tubes, mounted flap wheels in particular are great.

- Longer Lifespan: Flap wheels typically last longer than many other abrasive discs, providing exceptional value for money because new abrasive layers are continuously exposed.

Types of High Speed Flap Wheels

1. Mounted Flap Wheels

- These wheels come with a spindle or shank and are ideal for precision finishing of internal surfaces, pipes, and intricate areas. Available in various diameters and grits, they are perfect for mold polishing and tool finishing.

Applications: Die polishing, inside tube cleaning, surface blending, and more.

2. Shaft Mounted Flap Wheels

- Similar to mounted flap wheels but with a more robust shaft, these are perfect for medium to heavy-duty grinding and surface conditioning.

Applications: Blending welds, finishing corners, deburring, and removing rust or paint.

3. Unmounted Flap Wheels

- These are large-diameter wheels without a shaft, designed to be mounted on bench grinders or other machines. Ideal for heavy-duty applications and wide surface finishing.

Applications: Plate finishing, large surface grinding, and preparation before painting or coating.

4. Spindle Flap Wheels

- These wheels are attached to machines with spindles and are used for continuous surface polishing at high speeds. They are great for mass production processes in industrial units.

Applications: Stainless steel finishing, aluminum polishing, and auto part rework.

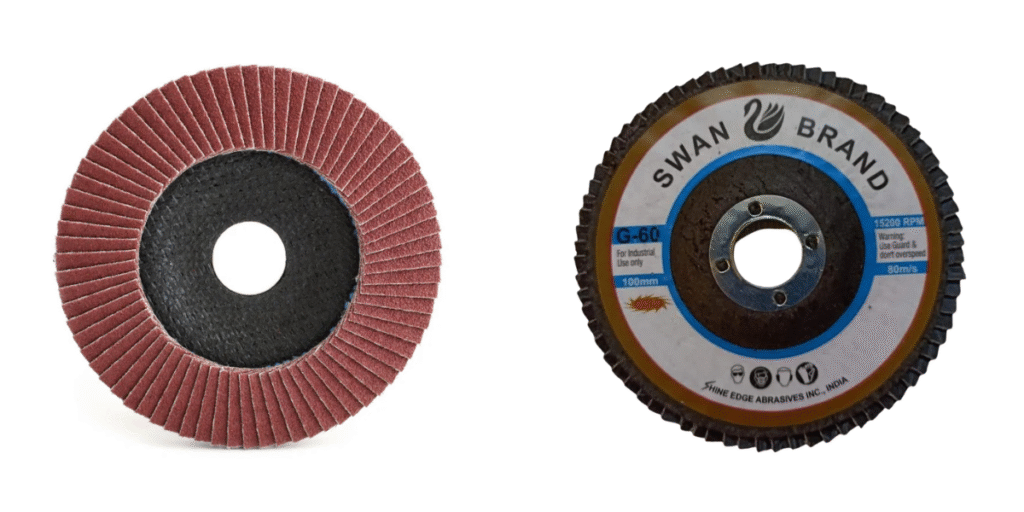

5. Flap Discs

- Though technically a different product, flap discs serve a similar purpose and are often grouped together. They consist of overlapping abrasive flaps arranged on a fiberglass or plastic backing plate.

Applications: Weld seam removal, surface cleaning, beveling edges, and finishing jobs.

Conclusion

High-speed flap wheels, which provide a potent blend of effectiveness, adaptability, and exceptional results, have completely changed how industries approach surface finishing. They are an essential tool in contemporary production and craftsmanship because of their capacity to minimize heat, conform to shapes, and produce a consistent cut. We are the best Best High Speed Flap Wheel Dealer.

However, working with an experienced and trustworthy dealer unlocks these tools’ full power. Selecting a supplier who places a high value on quality, provides a wide selection, and offers knowledgeable assistance means that you are investing in a collaboration that will improve both the caliber of your work and your productivity.