Alcon Flap Disc For Welding Finishing

Table of Contents

Introduction

Shine Edge is the manufacturer and supplier of coated & Bonded Abrasives products. We have state of art facilities to make Fibre discs, Flap discs, Flap wheels, lamellar wheels, and cutting wheels. Also, we are authorized distributors of Orient Abrasives, John Okay, Polymak, Karbit, and Rohit Cutting Tools.

Until the finish is flawless, the welding job isn’t really finished. Sharp edges, uneven surfaces, and discolouration can all lower the caliber and appeal of your work. The correct abrasive is essential in this situation, and Alcon flap discs are revolutionary for welding finishing. We at Shine Edge, in Ghaziabad, Uttar Pradesh, India, are pleased to provide premium GAlcon flap discs to assist you in achieving a perfect finish because we recognize how important it is. We are the best Alcon Flap Disc For Welding Finishing Supplier.

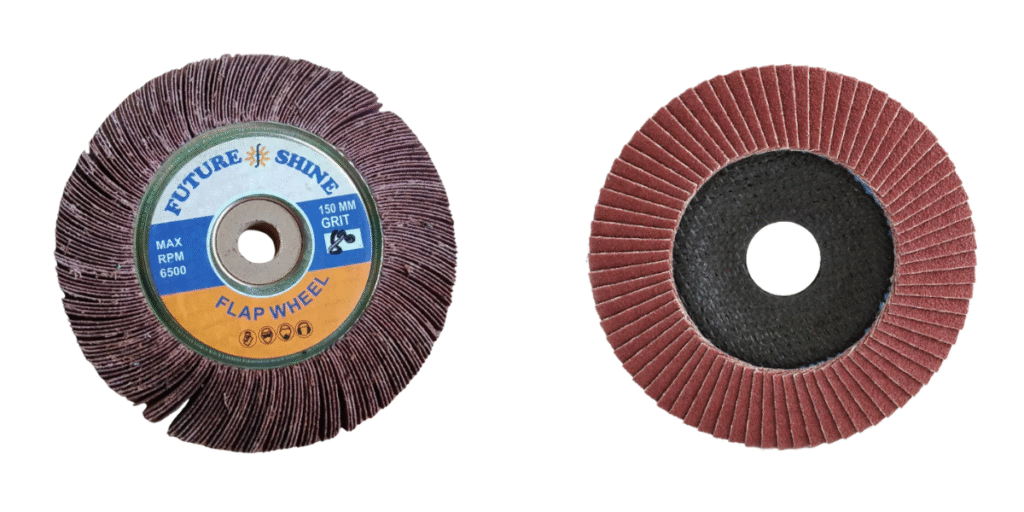

What are Flap Discs

Think of it like sandpaper, only stronger, more adaptable, and made for power tools. In essence, a flap disk is just that. It consists of a backing plate with overlapping abrasive flaps attached. As the disc rotates, these flaps which are usually composed of ceramic, zirconia alumina, or aluminum oxide grind and mix surfaces. Compared to conventional grinding wheels, the overlapping design offers a number of benefits that result in more regulated, cooler, and smoother material removal. We are the best Alcon Flap Disc For Welding Finishing Dealer

Why Choose Shine Edge

- Unmatched Durability and Lifespan: Our discs are engineered with a high-quality fiberglass backing and premium abrasive materials. This means they last significantly longer than cheaper alternatives, reducing your need to constantly replace them. A single Shine Edge Alcon flap disc can do the work of several traditional grinding wheels and sanding discs, saving you money and valuable work time.

- Superior Performance: We understand the importance of a clean, high-quality finish. Our Alcon discs are designed to minimize heat buildup, prevent gouging, and deliver a consistent, smooth surface every time. Whether you’re working on a heavy-duty industrial project or a delicate art piece, our discs will give you the results you need.

- Safety and Reliability: The safety of our customers is our top priority. Shine Edge Alcon flap discs are manufactured to the highest standards, ensuring they are reliable and safe to use when following proper safety guidelines. Our fiberglass backing provides excellent vibration absorption, making your work more comfortable and controlled.

- Customer-Focused Support: We’re passionate about what we do. Our team at Shine Edge is always ready to help you choose the right tool for your specific application. We don’t just sell you a product and send you on your way; we partner with you to ensure you get the most out of your tools.

- Large Selection: To satisfy all of your welding finishing requirements, we keep an extensive inventory of ALCON flap discs. We offer the appropriate disc for you, whether you require a fine grit for a clean, polished finish or a coarse grit for quick debris removal. Our experienced staff can even assist you in choosing the optimal choice for your particular use case.

- Commitment to Customer Satisfaction: At Shine Edge, customer satisfaction is our top priority. We are dedicated to providing you with a positive buying experience, from your initial inquiry to after-sales support. We stand behind the quality of our products and are always ready to assist you.

- Building Long-Term Relationships: We aim to be more than just a supplier; we want to be your long-term partner in success. We believe in building strong, lasting relationships with our customers based on trust, reliability, and exceptional service.

- Expert Advice and Support: Our team at Shine Edge consists of experienced professionals who are passionate about helping you find the right tools for your job. We can provide expert advice on selecting the appropriate ALCON flap disc for your welding finishing tasks and offer tips for achieving the best results. Feel free to reach out with any questions you may have.

Applications of Alcon Flap Disc

1. Weld Grinding and Blending

- One of the primary uses of Alcon Flap Discs is to grind and blend welds. After welding, seams often have rough edges or excess material. Flap discs smooth these welds, giving a professional and polished finish.

2. Surface Preparation

- Before painting, coating, or finishing metal surfaces, it’s important to remove rust, oxidation, or imperfections. Flap discs are perfect for surface preparation, ensuring adhesion and a flawless finish.

3. Deburring

- After cutting or machining metal, edges can be sharp or uneven. Alcon Flap Discs help in deburring, making surfaces safe and smooth.

4. Polishing and Finishing

- For industries like automotive, aerospace, and metal fabrication, a shiny and smooth finish is crucial. Flap discs can be used for polishing and finishing, giving metals a high-quality look.

5. Industrial Fabrication

- From construction to manufacturing plants, flap discs play an important role in industrial fabrication. They help in shaping, smoothing, and finishing metal parts efficiently.

6. Metal Fabrication and Welding Workshops

- In welding shops, flap discs are essential for finishing welded joints. They remove slag, spatter, and sharp edges to give a smooth, professional look.

7. Automotive Industry

- From car frames to engine components, flap discs help in smoothing weld seams and prepping surfaces for paint, ensuring high-quality automotive finishes.

8. Construction and Structural Steel

- Steel beams, railings, and other structural elements often need finishing after welding. Alcon flap discs speed up the process while ensuring a uniform appearance.

Table of Specifications Alcon Flap Disc

| Feature | Specification |

|---|---|

| Material | Alcon Flap Disc |

| Grit Range | 40, 60, 80, 120 |

| Material | Aluminum Oxide, Zirconia |

| Backing Type | Fiberglass, Plastic |

| Maximum RPM | 13,300 RPM |

| Thickness | 6mm – 8mm |

| Applications | Grinding, Blending, Finishing Welds |

| Suitable Metals | Steel, Stainless Steel, Aluminum, Alloy |

Benefits of Alcon Flap Discs

- Superior Material Removal: The overlapping flap design allows for aggressive material removal, making quick work of weld beads, spatter, and imperfections. You’ll spend less time grinding and more time on the next stage of your project.

- Smoother Finish: Unlike rigid grinding wheels that can leave deep gouges, Alcon Flap Discs provide a smoother, more consistent finish. The flexibility of the flaps allows them to contour to the workpiece, resulting in a blended surface that requires minimal further work.

- Longer Lifespan: The layered construction of flap discs means that as one layer of abrasive wears away, a fresh layer is exposed. This significantly extends the life of the disc compared to traditional grinding wheels, saving you money in the long run.

- Cooler Operation: The design of Alcon Flap Discs promotes better airflow, which helps to dissipate heat quickly. This cooler operation prevents the workpiece from overheating and reduces the risk of discoloration or distortion, especially on thinner materials.

- Reduced Vibration and Noise: Compared to grinding wheels, flap discs produce less vibration and noise, leading to a more comfortable and safer working environment. This is particularly beneficial for those who spend long hours on grinding and finishing tasks.

- Enhanced Control and Precision: The flexibility of the flaps provides better control over the grinding process. You can achieve precise material removal and blend surfaces seamlessly, resulting in a professional-looking finish every time.

- Versatility: Alcon Flap Discs are suitable for a wide range of materials, including steel, stainless steel, aluminum, and other alloys. They are also effective for various applications, from weld blending and deburring to rust removal and surface preparation for painting or coating.

- Increased Productivity: The combination of aggressive material removal, smoother finish, and longer lifespan translates to increased productivity. You’ll be able to complete your projects faster and with less downtime for changing discs.

- Safety: The controlled and less aggressive nature of flap discs compared to some grinding wheels can contribute to a safer working environment by reducing the risk of accidental gouging or workpiece damage.

- Cost-Effectiveness: While the initial cost might be slightly higher than some traditional abrasives, the longer lifespan and improved efficiency of Alcon Flap Discs ultimately make them a more cost-effective solution in the long run. You’ll use fewer discs and spend less time on each project.

Types of Alcon Flap Discs

1. Aluminum Oxide Flap Disc

- Best for: Mild steel and general-purpose metal finishing

- Features: Durable, provides smooth finish, suitable for high-speed operations

- Application: Ideal for weld blending, rust removal, and surface smoothing

2. Zirconia Flap Disc

- Best for: Stainless steel and tougher metals

- Features: Long-lasting, aggressive material removal, heat-resistant

- Application: Heavy-duty grinding, deburring, and welding seam removal

3. Ceramic Flap Disc

- Best for: Stainless steel and high-strength alloys

- Features: Extremely durable, high grinding efficiency, self-sharpening

- Application: Industrial metal finishing, heavy fabrication projects

4. Fiber Backed Flap Disc

- Best for: Light to medium grinding tasks

- Features: Flexible, easy to handle, provides smooth finishing

- Application: Perfect for welding seam finishing and detailed surface work

5. Plastic or Resin Bonded Flap Disc

- Best for: Precision finishing tasks

- Features: Less aggressive, fine finishing, reduces scratches

- Application: Automotive, furniture, and decorative metalwork

Conclusion

The quality of your tools has a direct effect on the caliber of your job in the metalworking industry. An important advancement in welding finishing technology, the Alcon Flap Disc provides a better, safer, and more effective substitute for conventional grinding wheels. It is an indispensable tool in any workshop because of its capacity to manage both forceful material removal and careful blending.

You can rely on Shine Edge to provide you the best welding finishing when you’re ready to advance your skills. Our experience and dedication to quality guarantee that you’ll always have the necessary equipment to get a perfect finish. Choose Shine Edge and let your work really shine instead of settling for less.