Abrasives Products For Automotive Industry

Table of Contents

Introduction

Shine Edge is the manufacturer and supplier of coated & Bonded Abrasives products. We have state of art facilities to make Fibre discs, Flap discs, Flap wheels, lamellar wheels, and cutting wheels. Also, we are authorized distributors of Orient Abrasives Products John Okay, Polymak, Karbit, and Rohit Cutting Tools.

A complicated machine, the automotive industry is a symphony of manufacture, engineering, and design. Even though we frequently admire the svelte exteriors and potent engines,Abrasives Products are a silent force that ensures the accuracy and quality of every vehicle. From sculpting raw materials to polishing the finished product, these seemingly basic elements are essential. This article explores the types, uses, and significance of abrasive materials used in the automotive industry. It also highlights Shine Edge’s contributions to this crucial industry. We are the best abrasives products provider for automotive industry.

What are Abrasives?

High-hardness materials called Abrasives Productsare used to remove material from a workpiece by friction, shape, grind, and polish it. Consider sandpaper, polishing chemicals, and grinding wheels as instances of Abrasives Products For Automotive Industry in function. From the initial shaping of metal sheets to the final buffing of the car’s paint, abrasives are crucial at almost every stage of production in the automobile industry.

Abrasives Products in Automotive Manufacturing: A Multi-Stage Process

From raw materials to the final product, an automobile goes through several stages in which abrasives are essential:

- Body-in-White (BIW) Preparation: The car’s skeleton, or BIW, goes through a number of abrasive-based procedures. Grinding wheels are used to smooth out joints and eliminate extra weld material. The surface is prepared for painting using abrasive belts and discs, which provide excellent adhesion and a perfect finish.

- Manufacturing of Engines and Powertrains: In the production of engines, accuracy is crucial. Crankshafts, camshafts, and other engine parts are ground with abrasives to attain the precise tolerances needed for optimum performance. Exact cylinder bore dimensions and surface polish are guaranteed by the honing process, which uses fine abrasives.

- Fabrication of Parts: Abrasive procedures are needed for a variety of parts, including suspension components, brake rotors, and calipers. For these parts to perform and last a long time, smooth surfaces and precise dimensions are guaranteed by grinding and polishing processes.

- Painting and Surface Finishing: An automobile’s final look is a key selling point. When getting the car body ready for painting, abrasives are essential. Sanding smoothes the surface for applying primer and paint by removing flaws. The painted surface is buffed using polishing pads and chemicals to provide a high-gloss, showroom-quality finish.

- Glass Manufacturing: Abrasive procedures are advantageous even for automobile windows. To ensure clarity and optical quality, the glass is shaped and smoothed using grinding and polishing.

- Tire production: Abrasives are used in the tire production process even though they are not a direct component of the vehicle. The tire molds are prepared and correct tire manufacture is ensured by buffing and grinding.

Types of Abrasives Used in the Automotive Industry

Numerous abrasive products, each intended for a particular use, are employed in the automotive industry:

- Grinding wheels are employed in shaping and heavy material removal processes. They are available in different grits and bonding materials based on the work at hand.

- Abrasive belts are utilized for curves and flat surfaces to be finished, sanded, and ground. Both roughing and finishing procedures can benefit from their high material removal rates.

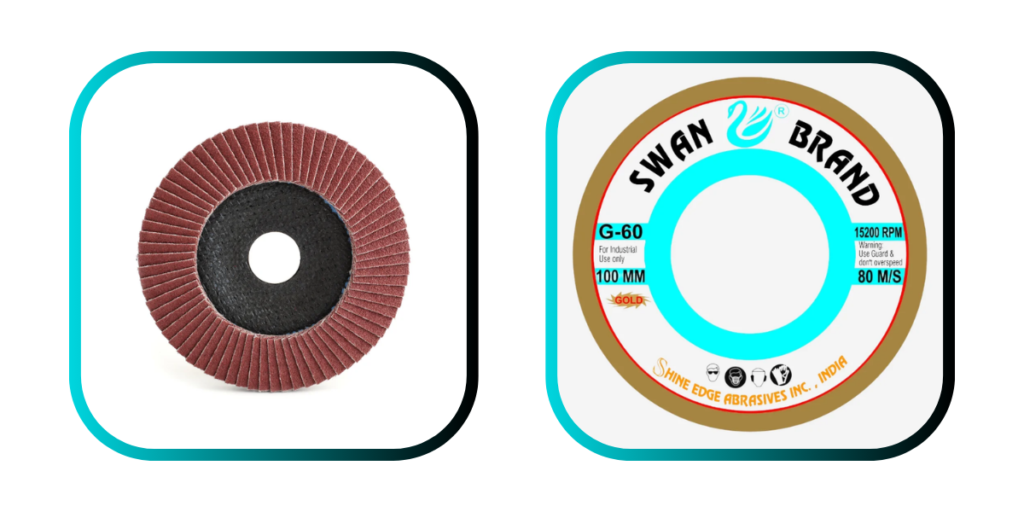

- Abrasive discs are multipurpose instruments for polishing, grinding, and sanding. They are frequently employed for finishing and surface preparation.

- Honing stones are employed to precisely polish cylinder bores and other important parts. They offer dimensional accuracy and extremely precise surface finishes.

- Polishing pads and compounds are used to give painted surfaces their ultimate polish. While polishing pads offer a smooth, glossy surface, polishing compounds eliminate small scratches and swirl marks.

- Coated abrasives are made up of abrasive granules that have been adhered to a supporting substance, including film, paper, or fabric. Sandpaper is a typical illustration. They are employed in many different finishing and sanding tasks.

The Importance of Abrasive Selection

For a given application, selecting the appropriate abrasive is essential to getting the best results. A few things to think about are: We are the best Abrasives Goods For Automotive Industry.

- Workpiece Material: Various materials call for various kinds of abrasives. For instance, a different abrasive is needed for grinding hardened steel than for sanding aluminum.

- Desired Finish: The grit size and abrasive type are determined by the necessary surface finish. Coarser grits are needed for rough grinding, and finer grits are needed for polishing.

- Application: The type and shape of abrasive are determined by the particular application. While polishing pads are used for final finishing, grinding wheels are utilized for heavy material removal.

- Equipment: The choice of abrasive is influenced by the equipment that is available. For particular kinds of abrasives, different machines are made.

Why Choose Shine Edge

In the ever-changing automotive manufacturing industry, efficiency and quality are critical factors. Shine Edge is aware of these requirements and provides a wide selection of premium abrasive materials made to specifically address the demands of the automobile sector. We are dedicated to offering our clients cutting-edge solutions that enable them to attain exceptional outcomes.

- High-performance Grinding Wheels: Designed for longevity and accuracy, our grinding wheels are perfect for tasks involving the removal of heavy materials and shaping.

- Multipurpose Abrasive Belts: Our abrasive belts provide outstanding performance in finishing, sanding, and grinding applications, guaranteeing consistent and seamless outcomes.

- Precision Abrasive Discs: Our discs have a long lifespan and exceptional material removal rates, making them ideal for a range of sanding and grinding applications.

- Specialized Honing Stones: Our honing stones provide the accuracy and surface finish needed for top performance on crucial engine parts.

- Premium Polishing Compounds and Pads: Our polishing solutions assist in giving painted surfaces a faultless, showroom-quality sheen.

- Tailored Solutions: We recognize that each application is distinct. We collaborate closely with our clients to create specialized abrasive solutions that satisfy their unique needs.

Shine Edge Product Specifications

| Product Name | Type | Grit Size | Backing Material | Application | Key Features |

|---|---|---|---|---|---|

| SE-CA-120 | Coated Abrasive | 120 | Cloth | Metal grinding, weld removal | Durable, fast cutting, long life |

| SE-CA-320 | Coated Abrasive | 320 | Paper | Surface preparation, paint removal | Flexible, good finish, cost-effective |

| SE-NW-180 | Non-Woven Abrasive | Medium | Nylon | Blending, finishing, light deburring | Conformable, non-loading, consistent finish |

| SE-BA-GC-80 | Bonded Abrasive | 80 | Vitrified | Heavy grinding, cutting | High stock removal rate, long life |

| SE-PA-CP-1000 | Polishing Compound | 1000 | N/A | Paint polishing, final finish | Removes swirl marks, high gloss finish |

| SE-DA-50 | Diamond Abrasive | 50 | Metal | Glass grinding, ceramic grinding | Extremely hard, long life, precise grinding |

| SE-CA-400 | Coated Abrasive | 400 | Film | Paint finishing, spot repair | Fine finish, consistent scratch pattern |

| SE-NW-Fine | Non-Woven Abrasive | Fine | Nylon | Final finishing, polishing | Flexible, non-scratching, excellent for blending |

| SE-BA-RO-60 | Bonded Abrasive | 60 | Resinoid | Cutting, grinding | Fast cutting, durable, versatile |

Conclusion

The unsung heroes of the automotive sector, abrasives are essential to each step of the vehicle’s development. Abrasive materials guarantee the quality, accuracy, and finish of every automobile, from shaping raw materials to polishing the finished product. Shine Edge takes pride in being one of the top suppliers of premium abrasive supplies to the automobile sector. We are the best abrasives products supplier for automotive industry.

We are dedicated to offering our clients cutting-edge solutions and knowledgeable assistance so they can accomplish their manufacturing objectives. To find out how we can help you streamline your car production processes, get in touch with Shine Edge right now. With our extensive selection of abrasive materials and dedication to client satisfaction, we are sure to become your go-to partner in the automotive sector.