Custom Grinding Wheels Manufacturer in Faridabad

Custom Grinding Wheels/Grinding Wheels Manufacturer in Faridabad/Custom Grinding Wheels Supplier in Faridabad/Grinding Wheels Manufacturer in Haryana/Grinding Wheels Supplier in Haryana/

Table of Contents

Introduction

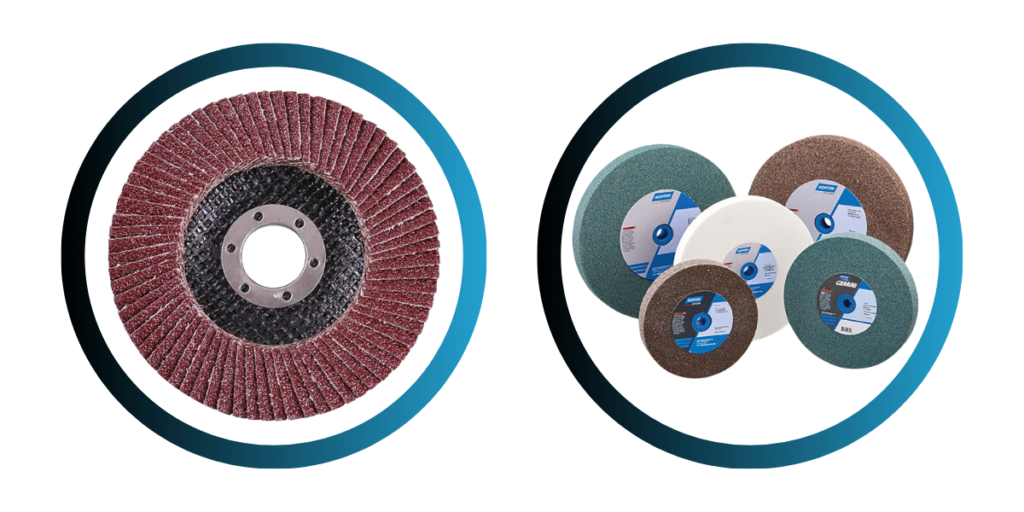

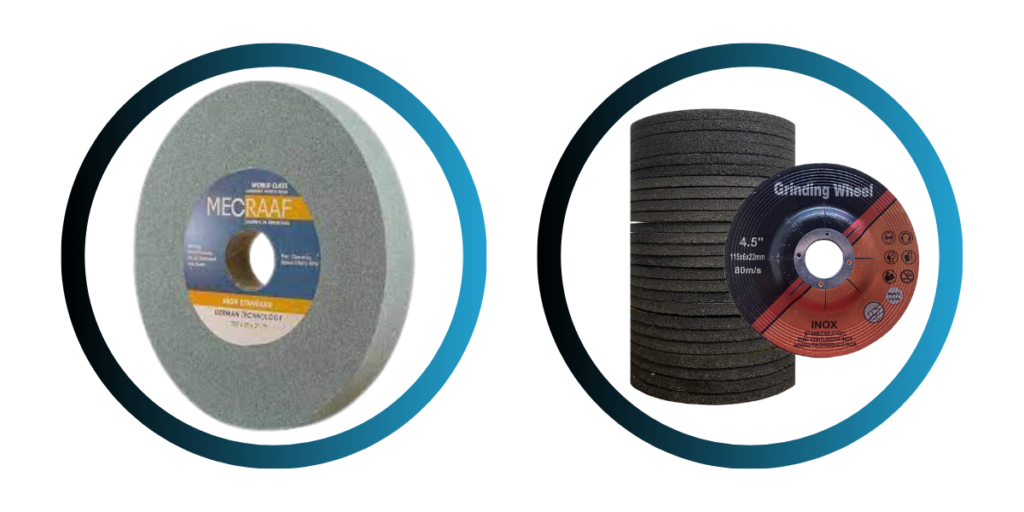

Shine Edge is the manufacturer and supplier of coated & Bonded Abrasives products. We have state of art facilities to make Fibre discs, Flap discs, Flap wheels, lamellar wheels, and cutting wheels. Also, we are authorized distributors of Orient Abrasives, John Okay, Polymak, Karbit, and Rohit Cutting Tools. We are the best Custom Grinding Wheels Manufacturer in Faridabad.

Precision is essential for high performance and efficiency in industrial applications. The grinding wheel is one of the most important instruments used in the engineering and manufacturing sectors to achieve this level of precision. The significance of custom grinding wheels, their uses, and the reasons Shine Edge, a top manufacturer of custom grinding wheels in Faridabad, is the ideal partner for all of your grinding requirements will all be covered in this blog.

What are Custom Grinding Wheels?

For the cutting, grinding, polishing, and shaping of materials like stone, metal, wood, and ceramics, grinding wheels are indispensable instruments. The abrasive materials used to make these wheels aid in the accurate and effective removal of material. Custom grinding wheels are made to fit particular needs depending on the kind of material being worked on, the desired finish, and the grinding speed, whereas standard grinding wheels can be used for a variety of tasks.

Special formulations are used to create custom grinding wheels that maximise performance, durability, and what is wanted. These wheels are extremely adaptable for a range of applications because they can be made in a variety of sizes, shapes, and abrasive materials.

Why Are Custom Grinding Wheels Important?

The advantages of custom grinding wheels are numerous.

- Accuracy and Precision: Because custom-made wheels are made to meet precise specifications, the grinding process is guaranteed to be accurate and efficient. This is especially crucial for sectors like manufacturing, aerospace, and automotive that need precise tolerances.

- Enhanced Performance: Manufacturers can raise the tool’s overall performance by customising the grinding wheel to fit particular materials and uses. Longer tool life, better surface finishes, and higher material removal rates result from this.

- Cost-Effective Solutions: By increasing the grinding process’s efficiency, custom grinding wheels can lower long-term costs even though they may demand a larger initial investment. They can also provide better value for money by lowering downtime and the need for frequent replacements.

- Optimised for Specialised Applications: Grinding wheels that are capable of performing particular tasks are necessary in a number of industries, including the automotive, metalworking, and tool manufacturing sectors. To satisfy these specific requirements, grinding wheels can be made, guaranteeing that the appropriate instrument is used for the task.

- Decreased Waste: Grinding wheels are made to work well and waste less material, which lowers costs and promotes sustainability.

Applications of Custom Grinding Wheels

Applications for grinding wheels vary from straightforward grinding jobs to complicated precision work, and they are utilised in many different industries. Typical uses include the following:

- Metalworking: To shape and grind metal components, custom grinding wheels are frequently utilised in metalworking. Custom wheels can be made to satisfy the particular requirements of metalworking tasks, ranging from cylindrical grinding to surface grinding.

- Tool Manufacturing: grinding wheels are crucial for shaping and sharpening cutting tools used by tool manufacturers. To guarantee that tools are sharp and honed to the proper angles, precision grinding wheels are required.

- Automotive Industry: For the purpose of grinding engine parts, gearbox parts and other essential automotive parts, grinding wheels are essential. In this industry, their capacity to withstand high temperatures and produce flawless finishes is essential.

- Woodworking: Chisels, saws, and blades are among the tools that can be sharpened with grinding wheels. They are a useful tool in woodworking because of their capacity to stay sharp and produce accurate cuts.

- Aerospace Industry: High-performance parts made of durable materials like titanium and alloys are ground and finished in the aerospace industry using grinding wheels. Since accuracy and quality are crucial in this field, custom wheels are necessary to get the intended effects.

- Construction and Mining: Tough materials like concrete, stone, and other heavy-duty materials are cut and ground using custom grinding wheels in the mining and construction sectors.

Why Choose Shine Edge: Best Custom Grinding Wheels Manufacturer in Faridabad

We at Shine Edge are proud to be one of Faridabad’s top producers of grinding wheels. Having worked in the field for many years, we are dedicated to giving our clients premium grinding solutions that satisfy their unique needs. We are the best Custom Grinding Wheels Supplier in Faridabad. The following explains how Shine Edge differs from the competition:

- Tailored Solutions: Because we recognise that every application is different, we provide grinding wheels that are specifically made to satisfy our customers’ requirements. We have the know-how to develop the ideal solution for your company, whether you require a grinding wheel for metal, ceramics, or composite materials.

- Modern Manufacturing Facility: Shine Edge produces custom grinding wheels using the newest machinery and technology. Every wheel is manufactured with precision and accuracy, adhering to the highest industry standards, thanks to our state-of-the-art facility.

- Experienced Engineers and Designers: To fully grasp each client’s unique needs, our team of talented engineers and designers works closely with them. We guarantee that our grinding wheels are designed and manufactured to the highest standards of quality and performance, starting with the initial consultation and ending with the delivery of the finished product.

- Superior Materials: For our grinding wheels, Shine Edge only uses the highest quality abrasive materials. We purchase our raw materials from reliable vendors to guarantee that every grinding wheel is strong, effective, and capable of handling demanding operating conditions.

- Broad Range of Applications: From metalworking and automotive to aerospace and construction, our grinding wheels are adaptable and can be utilised in a variety of industries. We have the ideal solution for you, regardless of how difficult your grinding task is.

- Competitive Pricing: Without sacrificing quality, we provide our custom grinding wheels at competitive prices. Our goal is to deliver value to our clients by offering cost-effective, high-performance solutions.

- On-time Delivery: We make every effort to guarantee that our grinding wheels are delivered on schedule because we recognise how important it is to meet deadlines. We guarantee that our customers receive their orders on time thanks to our effective production process and robust logistics network.

Industries That Benefit from Custom Grinding Wheels

For industries that demand extreme precision and specialised procedures, custom grinding wheels are crucial. The following are a few sectors that our grinding wheels help:

- Automobile Sector

Engine blocks, gears, crankshafts, and brake parts are among the parts made with grinding wheels. High surface finishes and precision are made possible for automakers by custom grinding wheels. - The Aeronautical Sector

Turbine blades, landing gear, and other precise parts are shaped and finished using grinding wheels in the aerospace sector. The precise specifications needed for aerospace applications are guaranteed by grinding wheels. - Tool and Die Industry

Cutting tools and dies are sharpened with custom grinding wheels. These wheels are made to manage high-precision tasks, guaranteeing that instruments stay precise and sharp for extended periods of time. We are the best Grinding Wheels Supplier in Haryana. - The Construction Sector

For cutting stone, concrete, and other construction materials, grinding wheels are necessary. The performance required to effectively cut through difficult materials is provided by custom wheels.

Conclusion: Custom Grinding Wheels Manufacturer in Faridabad

In many different industries, custom grinding wheels are crucial equipment for attaining accuracy and productivity. To achieve the best results, whether you work in woodworking, automotive, aerospace, or metalworking, you need the right grinding wheel. The best products catered to your needs are available from Shine Edge, a reputable manufacturer of custom grinding wheels in Faridabad. We are certain that we can assist you in achieving exceptional performance in all of your grinding applications thanks to our experience, premium materials, and customer-focused methodology. We are the best Grinding Wheels Manufacturer in Haryana.

Get in touch with Shine Edge right now to place an order or for more information.